A commercial asphalt paving project is a significant investment that requires careful planning and execution. Whether you’re paving a parking lot, roadway, or industrial space, understanding the process can help minimize disruptions and ensure a smooth, high-quality result. Here’s what to expect from start to finish when you work with The Pavement Group.

1. Initial Planning and Site Assessment

Before any work begins, a thorough site assessment is conducted to evaluate the existing conditions. This includes:

- Measuring the area to determine material and labor requirements.

- Checking for drainage issues and necessary grading adjustments.

- Identifying any structural weaknesses in the existing pavement (if applicable).

- Securing necessary permits and ensuring compliance with local regulations.

A well-planned project ensures efficiency and long-lasting results.

2. Site Preparation and Demolition

For new asphalt installations, the site is cleared of debris, vegetation, or existing pavement. If replacing or overlaying old asphalt, the deteriorated sections are removed using milling machines.

Other key steps include:

- Excavation to establish a proper base.

- Grading the surface for water drainage.

- Compacting the sub-base to prevent future shifting or sinking.

Proper site preparation is critical to extending the lifespan of the asphalt.

3. Base Layer Installation

The foundation of the asphalt pavement consists of compacted aggregate materials. This base layer provides stability and prevents premature cracking.

- A strong base is essential for handling heavy commercial traffic.

- The thickness of the base layer varies depending on the intended use of the asphalt surface.

Once the base is installed and compacted, a proof roll test may be conducted to ensure proper load-bearing capacity.

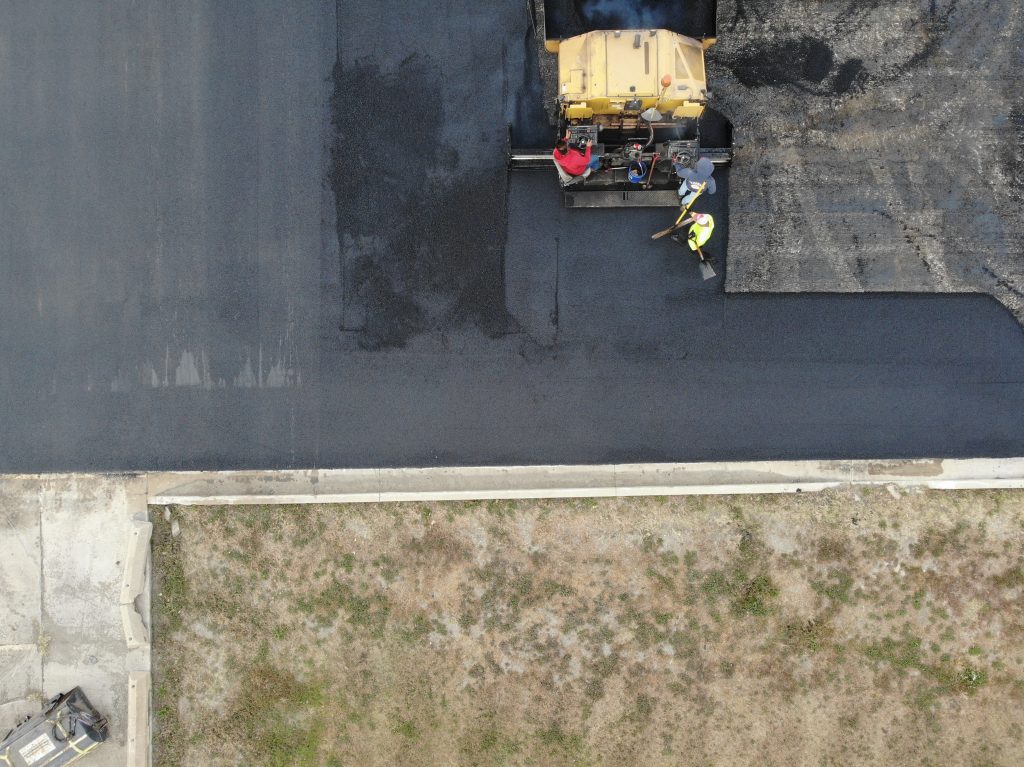

4. Asphalt Application

Once the base is ready, the asphalt is applied in multiple layers:

- Binder Layer – A strong, load-bearing layer that enhances durability.

- Surface Layer – A smooth, high-quality layer that provides traction and aesthetics.

The asphalt is heated to an optimal temperature and laid down using paving machines. Rolling and compaction follow immediately to create a uniform surface.

5. Curing and Striping

After the asphalt is applied, it needs time to cure. While it cools quickly, full curing can take several days.

- Traffic should be restricted for at least 24-48 hours.

- Striping, signage, and pavement markings are applied once the surface is fully set.

- Sealcoating may be scheduled in the future to enhance longevity.

6. Final Inspection and Maintenance Recommendations

A final inspection ensures the asphalt meets quality and safety standards. Contractors will check for:

- Proper drainage and grading.

- Even surface texture with no cracks or depressions.

- Compliance with project specifications.

Property owners should receive maintenance recommendations to extend the life of their new pavement, including:

- Regular sealcoating and crack filling.

- Keeping the surface clean from debris and chemicals.

- Addressing minor repairs promptly to prevent larger issues.

A well-executed commercial asphalt paving project enhances property functionality, safety, and aesthetics. By understanding the key steps involved, businesses can better prepare for the process and ensure long-term pavement performance.

If you’re planning a commercial asphalt paving project, contact us to discuss your needs and receive a customized quote.