Restoring a massive parking lot takes precision, planning, and passion. The Pavement Group recently completed a 403,000 square-foot asphalt restoration project for Orchard Hill Church, showcasing expertise in crack filling, sealcoating, and line striping.

This project was more than just pavement work. It was about creating a safe, beautiful, and functional space for the community. Orchard Hill Church in Pennsylvania needed a large-scale restoration that balanced durability, appearance, and cost-efficiency.

The Pavement Group delivered exactly that.

The Challenge: A Weather-Worn Parking Lot in Need of Renewal

Over time, Orchard Hill Church’s parking lot had endured years of weather exposure, vehicle traffic, and aging asphalt. Cracks, fading lines, and water drainage issues created both safety and visual concerns.

The church’s leadership team wanted a long-lasting solution without interrupting their daily operations and weekend services.

The main challenges included:

- Managing a large-scale project within a tight schedule.

- Maintaining access for staff, visitors, and events.

- Addressing cracks, wear, and structural deterioration across 403,000 square feet.

- Delivering results that would last for years with minimal maintenance.

The Pavement Group stepped in with a detailed, customized approach.

The Assessment: Precision and Planning

Every successful restoration begins with assessment. The Pavement Group’s pavement specialists conducted a thorough inspection of the entire 403,000 sq. ft. lot.

They analyzed:

- Crack depth and width variations.

- Drainage patterns across the lot.

- Traffic flow and high-stress areas.

- Previous sealant conditions and surface wear.

Using advanced pavement evaluation tools, they developed a restoration plan tailored specifically for Orchard Hill Church’s property.

The final strategy included comprehensive crack filling, two-coat sealcoating, and new line striping. Executed in carefully managed phases to minimize disruption.

The Plan: Step-by-Step Asphalt Renewal

The Pavement Group’s team designed a project plan that emphasized efficiency and safety. Each stage was scheduled with precision to ensure smooth workflow and timely completion.

Phase 1: Crack Filling

Cracks were first cleaned using high-pressure air to remove debris and moisture. Then, a hot rubberized crack sealant was applied to prevent water infiltration and extend pavement life.

This step alone helps reduce further asphalt deterioration by up to 50%.

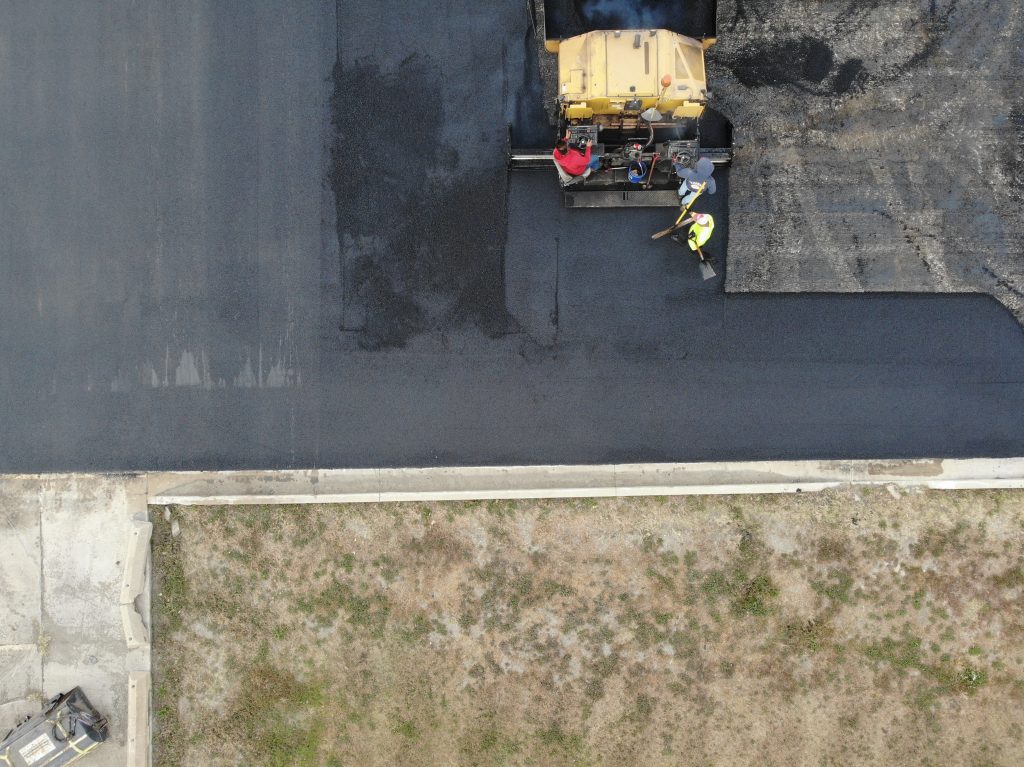

Phase 2: Sealcoating

Once the cracks were filled, it was time for sealcoating. The critical layer that protects and beautifies the surface.

Two coats of commercial-grade sealer were applied using a spray-and-squeegee method. This ensured even coverage, UV protection, and a deep black finish.

Sealcoating not only enhances curb appeal but also protects the asphalt from oxidation, oil spills, and harsh weather.

Phase 3: Line Striping

After the surface cured, the team completed precise line striping and pavement markings. Using high-visibility traffic paint, they redefined parking stalls, directional arrows, fire lanes, and accessible spaces.

The updated striping improved traffic flow, enhanced safety, and gave the property a fresh, professional appearance.

The Execution (Collaboration and Communication)

For a project of this scale, communication was key. The Pavement Group coordinated directly with the church’s facility manager to schedule work around community activities and services.

Each phase was completed section by section to ensure continuous access to the property. The crew worked efficiently, often in early mornings and evenings, to avoid disruption.

Weather conditions were closely monitored, ensuring optimal temperature and humidity for every coating and sealant application.

The result? Zero downtime for Orchard Heal Church and an on-time project completion.

The Results: A 403,000 Sq. Ft. Transformation

After completion, Orchard Hill Church’s parking lot looked brand new. The once-cracked, weathered asphalt was now sleek, durable, and ready for years of use.

Visual Results

- Deep black finish from premium sealcoating.

- Crisp, bright lines improve visibility and safety.

- Clean, uniform surface that enhanced curb appeal.

Functional Results

- Extended pavement lifespan by several years.

- Improved water runoff and reduced pooling areas.

- Reduced long-term maintenance costs.

The project not only improved the property’s appearance but also enhanced safety for the hundreds of vehicles that use the lot weekly.

Testimonial From Orchard Hill Church Facilities Team

“We were amazed by the professionalism and organization. The Pavement Group delivered top-quality results while keeping our operations running smoothly. Our parking lot now looks incredible—better than ever!”

— Facilities Director, Orchard Hill Church

This feedback reflects the team’s commitment to excellence, communication, and customer satisfaction.

The Pavement Techniques That Made the Difference

Delivering a project of this scale required industry-leading methods and equipment. The Pavement Group’s success relied on advanced technology and experienced crews.

1. Hot-Pour Crack Sealant

Unlike cold-applied fillers, the hot-pour method ensures deeper penetration and better adhesion. It prevents water from weakening the subbase and stops cracks from spreading.

2. Dual-Method Sealcoating Application

By combining spray and squeegee techniques, the coating adhered perfectly even on rough surfaces. This method ensures maximum protection and aesthetic appeal.

3. High-Visibility Striping

Traffic paint was selected for durability and clarity. Its reflective qualities ensure visibility in both day and night conditions.

The Impact: Community and Longevity

For Orchard Hill Church, the new parking lot meant more than smoother pavement. It meant safety for families, accessibility for events, and pride in their facility.

The updated space supports thousands of weekly visitors with easy navigation and reliable infrastructure.

For The Pavement Group, this project became a model of exceptional pavement restoration. Combining precision, teamwork, and craftsmanship at scale.

Lessons Learned and Best Practices

Large asphalt restorations require detailed planning and adaptive execution. Key takeaways from the Orchard Heal Church project include:

- Phased Scheduling Works: Dividing work sections keeps properties operational.

- Quality Sealants Pay Off: Investing in premium materials increases lifespan and reduces maintenance needs.

- Communication is Everything: Daily updates kept all stakeholders aligned and informed.

- Local Expertise Matters: Understanding regional weather and surface conditions ensures durable results.

These best practices now guide future large-scale projects across commercial and community spaces.

Sustainability and Eco-Friendly Practices

Modern asphalt restoration isn’t just about durability. It’s about responsibility. The Pavement Group used eco-conscious materials and methods wherever possible.

- Sealants were low-VOC and environmentally safe.

- Recycled asphalt content minimized waste and cost.

- Equipment was optimized for efficiency, reducing fuel usage and emissions.

These choices align with both industry standards and community values for sustainable construction.

The Future: Lasting Partnerships in Pavement Care

The Orchard Hill Church project reinforced a core principle. Great results build lasting relationships. The Pavement Group remains the church’s trusted partner for ongoing maintenance, seasonal inspections, and future upgrades.

Routine care, such as annual sealcoating and periodic line striping, ensures the lot continues to look sharp year after year.

This proactive approach saves the church money and preserves its investment long-term.

Partner with The Pavement Group for Professional Asphalt Restoration

Whether you manage a church, school, retail center, or corporate facility, your pavement reflects your organization’s commitment to quality and safety.

From small repairs to multi-acre resurfacing, we deliver results that last. Call The Pavement Group to schedule a consultation.

Let’s create a surface that’s built to endure, smooth, strong, and stunning.

Frequently Asked Questions

1. What is included in a full asphalt restoration project?

A full asphalt restoration includes crack filling, sealcoating, and line striping to improve durability and appearance. This process restores surface strength, prevents water damage, and extends pavement life. It’s ideal for large properties like churches, schools, and commercial lots.

2. How long does asphalt crack filling last?

Properly applied crack filling can last up to three to five years, depending on weather and traffic conditions. It seals cracks to prevent water intrusion and further pavement deterioration. Regular maintenance helps maximize its lifespan and effectiveness.

3. What are the benefits of sealcoating asphalt surfaces?

Sealcoating protects asphalt from UV rays, oil spills, and moisture damage. It restores the pavement’s deep black color, improving curb appeal and surface longevity. For large areas like parking lots, it also enhances safety by creating a smoother driving surface.

4. Why is line striping important after sealcoating?

Line striping ensures proper traffic flow, organized parking, and clear visibility on freshly sealed asphalt. It improves safety for drivers and pedestrians while maintaining compliance with accessibility standards. Fresh striping also gives any property a polished, professional look.

5. How often should commercial asphalt be sealcoated?

Most experts recommend sealcoating every two to three years, depending on climate and traffic volume. This routine maintenance helps prevent cracks, fading, and surface wear. Regular sealing saves money by avoiding premature asphalt replacement.

6. What is the best temperature for applying sealcoating?

Sealcoating performs best when temperatures are between 50°F and 85°F with dry conditions. Warm weather allows proper curing and strong adhesion. Applying sealer in ideal temperatures ensures a longer-lasting, even finish.

7. How long does it take for sealcoating to dry completely?

Sealcoating typically dries within 24 to 48 hours under favorable weather conditions. Drying time can vary based on humidity, sunlight, and surface thickness. It’s best to keep vehicles off the surface until the sealer fully cures.

8. What are the most common causes of asphalt cracking?

Asphalt cracks often form from water infiltration, freeze-thaw cycles, and heavy traffic loads. Poor drainage and lack of maintenance can accelerate the damage. Regular inspections and timely crack filling help prevent larger structural issues.

9. How large can a commercial asphalt restoration project be?

Commercial asphalt restorations can range from small parking lots to multi-acre facilities over 400,000 square feet. Large-scale projects require detailed planning, phased scheduling, and specialized equipment. With proper management, even extensive restorations can be completed efficiently and safely.

10. What are the long-term benefits of asphalt maintenance?

Routine asphalt maintenance extends pavement life, enhances appearance, and improves safety for vehicles and pedestrians. It reduces repair costs by preventing severe damage early on. Consistent care also boosts property value and public perception.