Now that fall is in full swing, facility managers should turn their attention to a crucial but often overlooked task: preparing parking lots, pathways, and other paved areas for the harsh winter months. Fall provides the perfect conditions for key pavement maintenance services, including sealcoating, crack filling, and pothole repair, which protect against costly damages caused by freeze-thaw cycles.

Let’s consider why autumn is ideal for pavement care and how taking the appropriate preventive steps can help facility managers prolong the life of their asphalt and concrete surfaces.

Pavement Maintenance: How Freeze-Thaw Cycles Impact Pavement

During winter, moisture seeps into small cracks and porous areas within the pavement. As temperatures drop, this trapped water freezes and expands, causing cracks to widen, surfaces to shift, and pavement to weaken. When the ice thaws, the process reverses, but the accumulated stress often results in widened cracks, potholes, and structural damage. This cycle repeats, accelerating the damage and escalating repair costs.

Fall pavement maintenance prevents these issues from getting worse by filling cracks and sealing surfaces, creating a protective barrier against winter weather.

Why Fall is Ideal for Sealcoating and Crack Filling

1. Optimal Weather Conditions:

Sealcoating and crack fill applications require mild temperatures and dry weather to properly bond with the pavement. Fall’s cooler, stable weather is ideal, allowing sealcoating to cure effectively and last through winter. Attempting these services too close to winter or during fluctuating temperatures risks poor bonding and ineffective results, ultimately costing more in future repairs.

2. Winter Damage Prevention:

Applying a sealcoat and crack filler in the fall helps keep out moisture and prevents freeze-thaw damage. By sealing off surface vulnerabilities, facility managers can keep water from seeping into the pavement, greatly reducing the risk of winter damage and improving safety for pedestrians and vehicles alike.

3. Extended Pavement Lifespan:

Routine maintenance like sealcoating and crack filling shields asphalt from UV rays, oxidation, and automotive chemicals, all of which can break down surfaces over time. A proactive fall maintenance plan can add years to the lifespan of a parking lot, reducing the need for costly repairs or replacement later.

4. Lower Liability and Safety Risks:

Cracks, potholes, and uneven surfaces create potential hazards for pedestrians and vehicles, increasing the risk of accidents and liability for property owners. Facility managers who prioritize fall maintenance provide a safer environment and lower the chances of winter injuries and potential lawsuits.

Key Pavement Maintenance Tasks for Fall

Facility managers should start their fall maintenance with a thorough pavement assessment. Here’s what to look for:

- Inspect for Cracks and Potholes: Document all visible cracks and potholes across high-traffic areas. Small cracks grow rapidly with freeze-thaw cycles, so prioritize repairs in busy areas to avoid costly problems.

- Evaluate Drainage Systems: Poor drainage accelerates pavement deterioration. Check for standing water or blocked drains that could compromise surface integrity, especially during winter.

- Examine Sealcoat Condition: If your pavement was previously sealcoated, check for any faded, patchy, or worn areas. Sealcoating that shows signs of wear is less effective against water and UV rays, so reapplication in fall is often necessary.

- Consider Traffic Patterns: Heavy traffic zones, such as entrances, exits, and loading areas, face faster wear and tear. Make these areas a focus in your sealcoating and repair plans.

Once you’ve assessed your pavement, implement these essential fall maintenance tasks:

- Crack Sealing: This involves filling cracks with a flexible material that adjusts with temperature changes. This process stops water from infiltrating pavement layers, reducing the chance of further winter damage.

- Sealcoating: This forms a protective layer that guards against water penetration, UV rays, and chemicals while also enhancing the appearance of your parking lots. A well-applied sealcoat in fall can last through multiple winters.

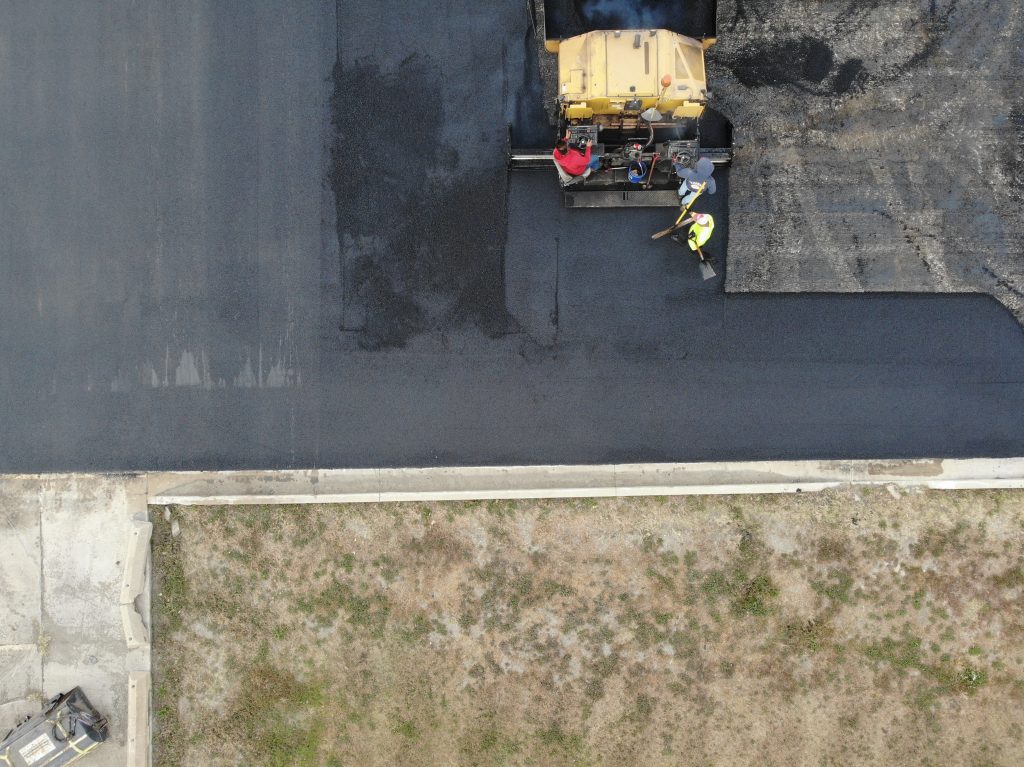

- Pothole Patching: Fall is ideal for patching potholes, as materials adhere better in cooler weather. Addressing potholes now prevents them from expanding during winter, minimizing hazards and reducing future repair costs.

- Line Striping and Re-Striping: Clearly visible pavement markings, such as parking lines and crosswalks, ensure smooth traffic flow and safety. Re-striping in the fall guarantees that markings remain visible throughout winter when visibility is often limited.

Selecting a Reliable Pavement Maintenance Partner

Successful pavement maintenance hinges on choosing a skilled contractor with expertise in sealcoating, crack filling, and repairs. Partnering with an experienced provider ensures that your parking lots and pathways receive the right care, using quality materials that meet winter conditions. Beware of low-cost service providers who may use subpar materials or cut corners—these can lead to frequent repairs, higher costs, and increased liability.

At The Pavement Group, we specialize in comprehensive pavement maintenance, offering facility managers a trusted partner for fall preparation. Our expert team uses top-tier materials and proven techniques to safeguard your pavement against winter’s challenges, ensuring long-term durability and performance.

Get Ready for Winter with Expert Fall Pavement Maintenance

Proactive fall maintenance is a wise investment for facility managers looking to protect their assets and minimize liability risks. By addressing cracks, potholes, and drainage issues now, you’ll preserve your pavement’s integrity, keep your property safe, and ultimately save on costly repairs. For reliable sealcoating, crack filling, and more, contact The Pavement Group today and schedule your fall maintenance services.